CYLINDER ACCOUNTABILITY TAG

CAT Tracking Systems for Your SCBA Compressor

Cylinder Accountability Tag (Tracking) System

Are you looking for 100% control of your SCBA cylinder refilling process? Look no further than the CAT II, Cylinder Accountability Tag System. The CAT II will retrofit all new and existing SCBA refilling stations.

You don’t need to buy a new SCBA compressor to realize the benefit of 100% cylinder accountability. The CAT II works with all brands of refill and charge stations and all SCBA and SCUBA cylinder brands.

- Control who uses your expensive refilling equipment

- Fill only to cylinder rated pressure, regardless of higher regulator settings

- Reject out of hydro, expired cylinders and cylinders you do not authorize

- Control inventory, produce refill, hydro due, and expiration reports

Cylinder Accountability Tag

Log into the CAT Cylinder Accountability Tag system with your Key-FOB or the optional fingerprint reader.

Keep unwanted and untrained users from accessing your compressor. Two levels of access:

- Administrator

- Refiller only

When an authorized user signs in, the main screen on the right appears. Simply choose what you wish to do by pressing the associated icon on the touch screen computer.

- Fill cylinders

- Generate reports

- Add, delete or edit cylinders

- Connect to Wi-Fi

- Cloud Sync

- Add, delete or edit users

- Logout

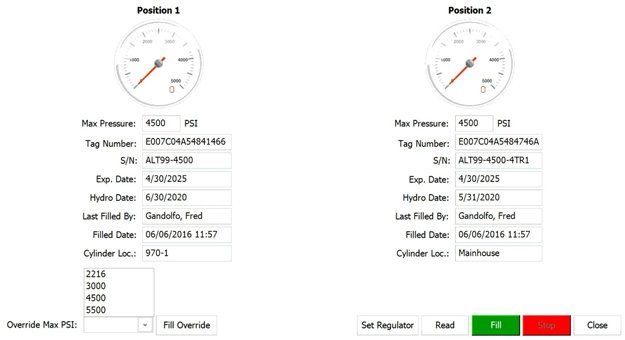

So Easy to Use

- The CAT II System is so easy to use and has no long and arduous training sessions and no confusing operational manuals to read. The intuitive screens guide you through the refilling process step by step. Anyone can safely fill cylinders with the CAT II System.

- The CAT II does not display useless information to confuse the inexperienced refiller. We subscribe to the theory that less is more. The fewer refilling operators have to interact with the equipment, the fewer problems we have, the more cylinders we can fill safely.

- Just install empty cylinders and press the fill icon the CAT II does the rest. It scans the cylinder's manufactured date, last hydro date and pressure. If something is wrong, the CAT II will reject the cylinder and tell you why. No guesswork, no errors, no forgotten reports. It is completely automatic and 100% safe and secure.

- The CAT II is available for both two and three-position fill stations. (4-position coming soon)

- To start filling SCBA cylinders, press the Green Fill button on the bottom of the touch screen. The CAT II will do the rest.

- The CAT II will scan the cylinders and determine if all cylinders are rated at the same pressure, are within hydrostatic testing dates, and have not expired.

- The CAT II will refill your cylinders only to their rated pressure

- The CAT II will update the database, assuring your refilling records are current and up to date.

- If your department did not authorize a cylinder to be refilled, the CAT II will reject it. Save the liability, refill only what you want to be refilled and only what is safe and legal to be refilled.

CAT II Will Provide a Permanent Record Of:

- Who refilled your cylinders by serial number and the time and date of refill

- The next hydro due date and cylinder expiration date

- Records are available to your email, in PDF or comma-separated data files

Intuitive and Simple to Use

CAT II is an intuitive, simple to use, gas cylinder refilling control and accountability system.

The original design of the CAT II Cylinder Accountability Tag system dates back to 2005. We recognized that many firefighters refilling a SCBA compressor were not checking or just didn’t know to check hydrostatic test and expiration dates. In other cases, compressor pressure regulators and flow control valves were set too high and too fast. Of course, not many kept their fill records as mandated by DOT and NFPA and those that did were illegible or missing pages.

Installing a CAT II System on your compressor air refill system, including cascade and mo-bile stations, will simplify the refilling process for your operators while affording you complete control and accountability of your cylinder refilling process and charge station.

Operation is simplicity at its finest. Just install your cylinders and press the fill icon. The CAT II will scan the cylinders within the fill enclosure and:

- Reject cylinders you have not authorized to refill in your department's equipment

- Reject cylinders that are out of hydrostatic retesting and/or lifetime expiration dates

- Refill cylinders only to their designed pressure rating, regardless of how high the ma-chines pressure regulator is manually set or not set at all. (This was important when SCBA pressures went from 2.2 to 4.5 and are even more important now, as some departments switch over to 5.5 while still filling 4.5, Ska-Paks and SCUBA)

- Protects cylinders from overfilling even “just a little to overcome that cooling pressure drop." Some departments overfill cylinders as a rule. After all, they claim, “It’s just a few hundred pounds." A few hundred pounds can stretch the cylinder, so it fails hydro, or worse, kills someone. The CAT II stops at the rated cylinder pressure, even if your regulator is set too high. We accommodate the large pressure drop by metering the pressure rise to the cylinders. (see our digital metered flow option for more control)

- Record the entire filling process for DOT, NFPA, and OSHA in easy to read, PDF, and various spreadsheets. The CAT II Provides accurate reports covering cylinder inventory, expiration date, hydro testing due date, cylinder refilling activity, by serial number, and includes time, date, and name of refilling operator. See our sample reports below:

CAT II Options

The CAT II Basic System contains everything you need to safely refill SCBA and SCUBA cylinders. Below are some options that will enhance the ability of your CAT II System.

CAT II System mounted on a Scott RevolveAir fill enclosure

CAT II System mounted on a vintage EAGLE BARON II. CRS

Why Did We Upgrade From RFID to Optical Scanning?

- It is against DOT— NIOSH—NFPA and OSHA regulations to apply aftermarket items to an SCBA and SCUBA cylinder... That includes RFID chips.

- Cylinder valve mounted and strapped on RFID tags can be inadvertently swapped to another cylinder. It is typically done during hydrostatic re-testing. If the tag does not match the cylinder, you do not have a 100% accountable system. You could be filling a cylinder that has expired, or you did not authorize it. The CAT II System is the only system that assures tag data, matches cylinder data even if valves or bumpers are swapped.

- There is only one manufacturer of SCBA cylinders that has a convenient and legal spot to place RFID Chips. However, those chips can be damaged in truck mounting brackets. Even this manufacturer cannot assure 100% accountability as their RFID chip is located on the easily swapped-out valve or valve bumper. Another manufacturer is promoting RFID tags bolted to the cylinder neck. That is not only illegal, according to the agencies, but there is no accountability in that design at all.

- Firehouse Systems recognized these issues early in the game. So about 3 years ago, we upgraded our original CAT RFID Accountability system to the CAT II Optical system. We needed to accommodate all cylinder brands while maintaining 100% accountability, and we did it, with the CAT II

- The CAT II uses optics to scan cylinder data. Optical tags can be secured anywhere on the cylinder we can aim our scanners. Since they cannot be removed without damaging the label, your cylinder data is 100 % assured.

- Our Labels also meet industry requirements because they double as hydro-static test labels. We can apply the CAT II label to any SCBA, SCUBA, Escape cylinder, or *Medical O2 cylinders regardless of the material of construction.

*(Our scanners and equipment are not explosion-proof rated and may not be suitable for explosive atmospheres which may be encountered when filling O2 cylinders).

Share On: